What is X-ray coating thickness guage?

Because the amount of energy discharged when X-ray is radiated on coating part has interrelation with material's thickness, the thickness is measured by using the below material's fluorescent X-ray excited or absorbed at the below material and coating thickness.

X-ray fluorescence of coating layer, Fluorescent X-rays detected at the bottom of the metal is a principle.

Technical Specification

Measurement Methods

|

Energy Dispersive X-ray Analysis

|

Sample Type

|

Multi-Layer, Solid/Liquid/Powder

|

X-ray Tube

|

W Target, 50kVp 1mA

|

Filter

|

5 Filter Auto Change

|

Detection System

|

SDD(Silicon Drift Detector), Si-Pin Diode(Peltier System)

|

Energy Resolution

|

135 eV FWHM at Mn Ka

|

Detection Element

|

AI(13)~U(92)

|

Measurement Area

|

0.1, 0.2, 0.4, 0.5, 1mm, auto change

|

Application Language

|

Korean/English/Chinese

|

Analyze Method

|

FP/Calibration Curve, Fluorescence, Absorption

|

Sample Monitoring

|

CCD Camera

|

Control System

|

DeskTop, USB Interface

|

Size of sample chamber

|

500 x 470 x 200mm(W x D x H), Wide PCB Support

|

Distance of Sample move

|

200 x 200 x 150mm(X x Y x Z)

|

Size

|

550 x 700 x 570mm(W x D x H)

|

Power

|

110/220VAC 50/60Hz

|

Weight

|

85kg(NET)

|

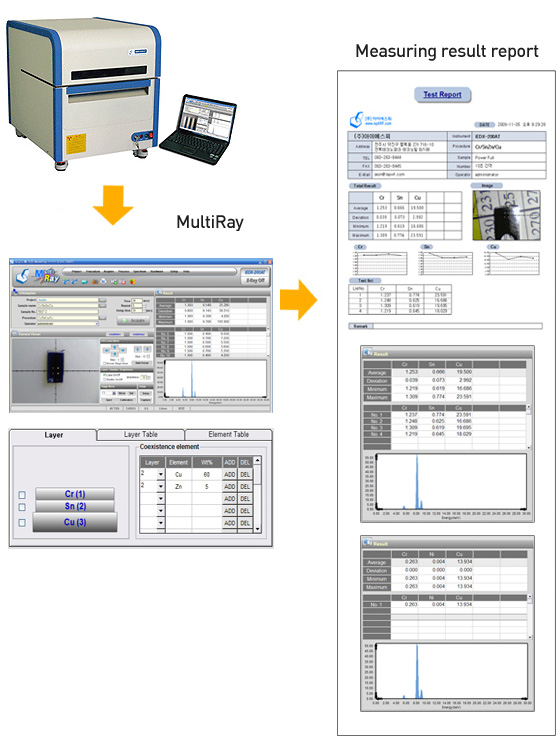

- It is unified product, which can measure coating thickness, analyzes hazardous material, and analyzes heavy metal.

- Non-Destructive/non-contact coating thickness measuring by using X-ray

- Various products measuring - analyze single coating, double coating, alloy coating, and coating liquid

- Through the function controlling auto-beam axis, perfectly match camera position with measuring point

- Automatic stage arrangement function

- Fields requesting/Non-Destructive test

- Automotive parts, electronic circuit board, electronic connector, and mobile phone & IT product

- Maintain accurate content in measuring high price coating thickness

- Measure coating thickness of precious metals

- Product research, product development, and quality control